Laser Cutting

Screw air Compressor

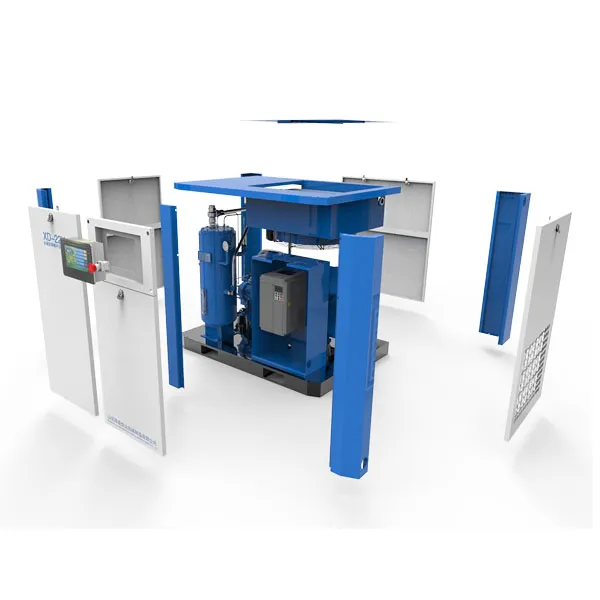

Innovative 4-in-1 combination screw air compressor for laser cutting.

- Adopting a freeze dryer with excellent performance, a compact rotary refrigeration compressor, and a high cooling capacity configuration scheme to ensure reliable operation under high-temperature conditions.

Small Footprint

Easy to Install

7-30 Bar Pressure

TABLE OF CONTENTS

- Machine parameters

- Excellent performance

- Applications

- Why choose this type?

- B2B Solution

- Compressor buying guide

Please consult our professional air compressor consultant and obtain the latest dealer quotation for 2024.

YSC - Laser Cutting Screw Air Compressor

Fixed Speed or VSD Optional

- 4-in-1 screw air compressor

- Tank mounted air compressor

- Integrated air compressor

- Combined air compressor

Model Series

YSC-Series

Base Type

Single / DoubleTank

Working Pressure

7-30 Barg

PSI

100psi – 435psi

Noise level dB(A)

62 ± 2

Tank Capacity

275L / 300L / 375L /500L / 600L

Power KW

5.5kw – 22kw

Power HP

7.5hp-30hp

Air Capacity (FAD)

0.7m³-4.2m³ / min

Driven Method

Direct Driven

Production Cycle

40 Units Every 21 Days

Option

PM VSD or Fixed Speed Type

Know -

Our

Fared

The 4-in-1 screw air compressor offers a balance of efficiency, reliability, and low operating costs for your industrial production.

Compact Design

The 4-1 model often features a compact and space-saving design, which is beneficial for installations in confined areas.

Low Maintenance

Due to its efficient design and fewer moving parts, the 4-1 screw air compressor requires less maintenance.

Consistent Air Pressure

It provides stable and consistent air pressure, which is crucial for many industrial applications that require a steady supply of compressed air.

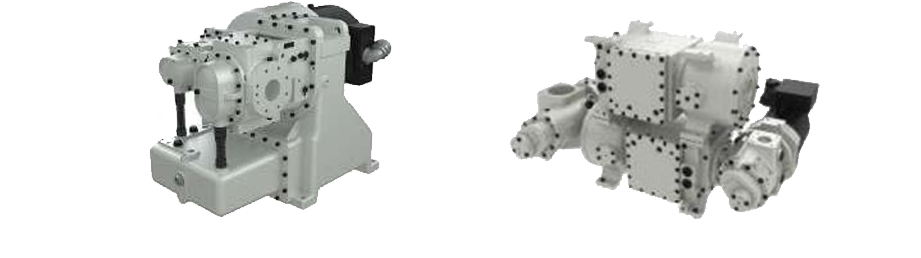

Compressor Airend

● New improved rotor profile

● R&D by YESHENG

● designed for 10 years of reliable operation

Compressor Motor

● Exceed IE4 standards

● Oil-cooled motor

● variable speed drive

● IP65 protection

Product Structure

● Integrated structure

● Screw air compressor

● Air tank with dryer

● 5-level filtration

Components

● The lifespan ≥ 8000 hours

● Reduce maintenance costs

● Originating from well-known suppliers

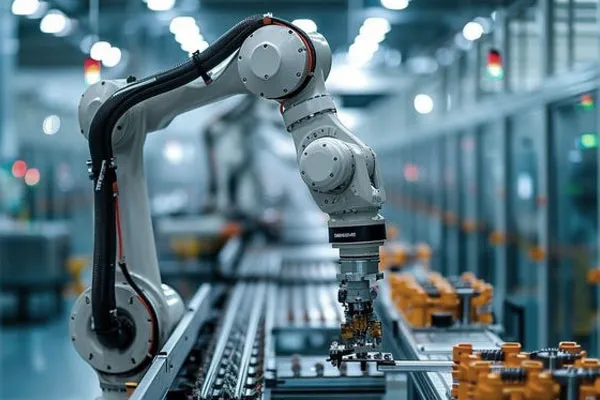

The laser cutting screw air compressor is widely used in various applications due to its versatility and efficiency.

Application of 4-in-1 Type Air Compressor

Laser Cutting Industry

Laser cutting equipment requires the use of air compressors with higher purity and pressure.

Automotive Industry

Used for spray painting, tire inflation, and operating pneumatic tools in garages and workshops.

Construction

Provides compressed air for tools like nail guns, drills, and other equipment on job sites.

Manufacturing

It combines functions like air compression, cooling, filtration, and drying, making it a compact.

Choose a reliable supplier of clean compressed air systems.

Why Choose Us as Your Supplier?

- low failure rate (<1%)

- Patent design, smaller size

- Reduce shipping costs by sea

- Compliant with ISO 8573 Standard

- Stable pressure and continuous output

- Multiple models available for you to choose

- Competitive prices to adapt to the local market

How can we ensure that our work is efficient and fast?

Production and Delivery of Orders

Confirm Order

Our consultants verify the order details with the customer, including general specifications and any custom requirements.

Perfect Details

Develop design solutions for customers while identifying the quickest delivery date and appropriate packaging for the products.

Production

We forward the customer order to the YESHENG factory to initiate product production.

Daily Updates

Our consultants will proactively update the production process of the machine for the customer.

Strict QC

Comprehensive pre-shipment testing and stringent inspection of compressors are conducted, and test reports are available.

Deliver

Our engineers use packing software to simulate container loading and confirm with customers to help them reduce transportation costs.

We aim to help our consumers create more profits and reduce production costs.

B2B (C) Solutions

B2B Solutions

- 10-30% advance payment

- 2-10% order discount

- Market protection, exclusive supply

- Expert monthly training

- Expert monthly training

B2C Solutions

- Fast 3-days delivery

- Support door-to-door delivery

- Factory direct shipment

- OEM compressored air system design

- On-site maintenance service

Laser Cutting Air Compressor Buying Guide

Combined air compressors compress air through a multi-stage process. Ambient air enters, gets compressed using a screw or piston, and is cooled to prevent overheating. The final output is filtered and dried, ensuring high-quality compressed air for various applications.

To select the right combined air compressor, assess your air requirements, including flow rate and pressure. Consider energy efficiency, maintenance costs, and the manufacturer’s support. Also, ensure the compressor fits your space and meets your operational demands.

A combined screw air compressor includes essential components: a screw compressor unit, cooler, air receiver tank, filters, and dryer. These parts work together to compress, cool, store, and purify the air, ensuring it meets the required quality for industrial applications.

Selecting between fixed-frequency and variable-frequency air compressors depends on your needs. Fixed-frequency models are cost-effective for steady demand, while variable-frequency models offer energy savings for fluctuating loads. Consider long-term costs and efficiency to make the best choice for your application.

In the laser cutting industry, choose an air compressor that provides high-pressure, clean, dry air to enhance cutting quality. Assess the required flow rate based on your machine’s specifications. Consider energy efficiency and reliability to minimize downtime and operational costs.

The price of combined air compressors varies widely based on factors like brand, capacity, and features. Generally, prices range from $400 to $20,000 or more. Additional costs may include installation, maintenance, and accessories. Always compare models and consider long-term efficiency when budgeting for your purchase.